Pimsacorp

Industrial Machining, Oil & Gas Energy Industry

Industrial machinery is crucial in manufacturing and production for several key reasons:

Precision and Accuracy: Industrial machining allows the production of parts and components with high precision and accuracy. This is essential to ensure that parts fit correctly in assemblies and meet stringent specifications, especially in industries such as aerospace, automotive and medical.

Custom Component Manufacturing: Through machining, it is possible to create customized components that cannot be obtained in a standard way. This is essential for designing and manufacturing unique or tailored parts for specific machinery and equipment needs.

Material Versatility: Machining can be applied to a wide range of materials, including metals, plastics, and composites. This allows the manufacture of components with different physical and mechanical properties, suitable for various applications and industrial requirements.

Quality and Performance: Machined parts are usually of superior quality in terms of surface finish and dimensional tolerances. This contributes to improved performance and durability of final products, reducing the risk of failure and increasing system reliability.

Long-term Cost Reduction: Although machining may have a high initial cost, the production of high quality and precision parts can reduce long-term costs by minimizing the need for adjustments and repairs, and by improving the efficiency of equipment.

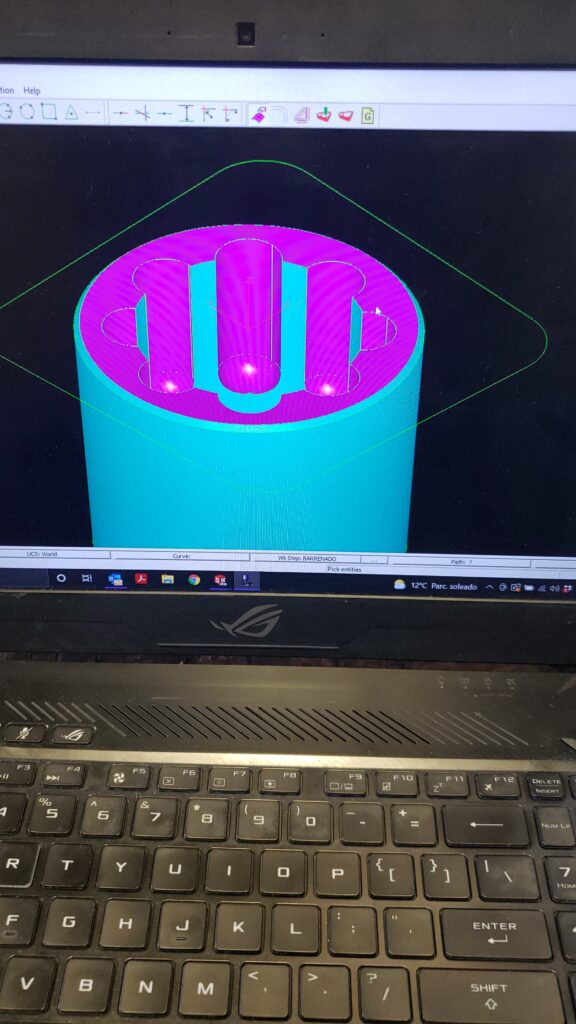

Prototyping and Product Development: Industrial machining is essential for prototyping and new product development. Enables engineers and designers to test and adjust components before mass production, ensuring that the final product meets desired requirements.

Production Efficiency: Industrial machining facilitates the mass production of components with high uniformity and repeatability. This is vital to maintaining high manufacturing efficiency and meeting market demands.

Innovation and Technology: Advances in machining technologies, such as computer numerical control (CNC) and precision machining, have enabled greater design and manufacturing capacity, driving innovation in engineering and industrial production.

Safety and Regulatory Compliance: In many industries, parts must meet strict quality and safety standards. Precise machining ensures that components are manufactured within the required specifications, ensuring compliance and safety of final products.

Adaptability: Machining allows rapid adaptation to changes in design or customer requirements. Machining machines can be reprogrammed or adjusted to produce new parts without the need for expensive tools or molds.

In short, industrial machining is vital for the production of high-quality and precise components, adaptation to individual requirements, efficiency in manufacturing and new product development. Its importance extends to many industries, contributing to technological progress and the improvement of product quality and performance.