pimsacorp

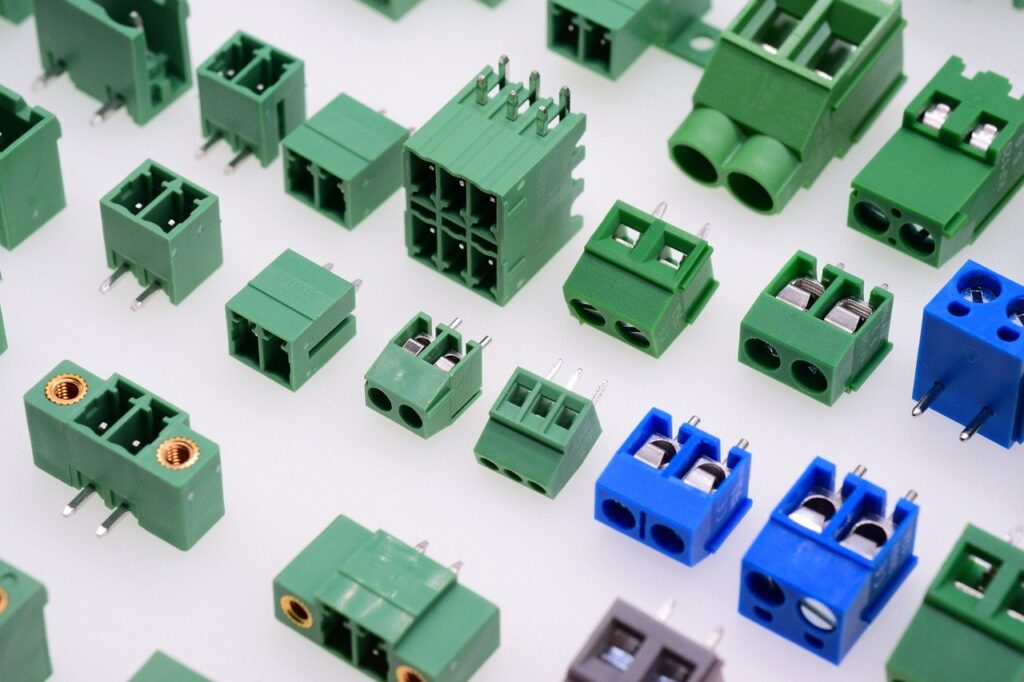

Supplys

Industrial supplies are critical to ensuring efficient, safe and continuous operations. Its importance lies in several key aspects:

1. Operational Continuity

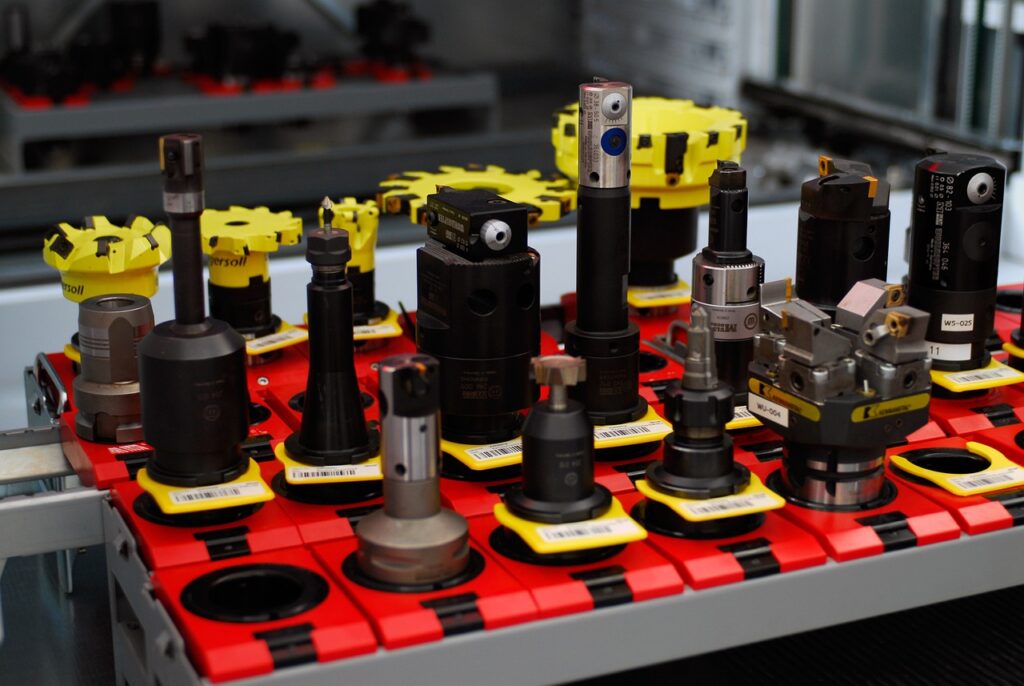

Minimization of Downtime: Industrial supplies, including tools, materials, spare parts and equipment, are essential to keep operations running. Lack of adequate supply can lead to costly outages and unplanned shutdowns.

Efficient Inventory Management: Having a constant and well-managed supply ensures that critical materials and components are always available, avoiding delays in production and delivery of products.

2. Quality and Efficiency

Process Optimization: High quality supplies are essential for the efficiency of industrial processes. Precise tools, durable materials and reliable equipment improve performance and productivity.

Reducing Waste: By using appropriate and quality supplies, you minimize waste and optimize the use of resources, which reduces costs and improves operational efficiency.

3. Safety at the workplace

Safety Compliance: Many industrial supplies, such as personal protective equipment (PPE) and safety devices, are critical to protecting workers and meeting safety regulations.

Accident Prevention: Access to proper safety supplies and maintenance helps prevent accidents, protecting both employees and equipment from potential damage.

4. Innovation and Competitiveness

Innovation Support: Modern and technologically advanced industrial supplies enable companies to improve their processes, adopt new technologies and remain competitive in a constantly evolving market.

New Product Development: Specialized materials and components are essential for the development and manufacture of new products, enabling companies to meet changing market demands.

5. Cost Reduction

Resource Efficiency: By ensuring the proper supply of materials and tools, companies can optimize their production processes, reduce waste and consequently operational costs.

Preventive Maintenance: Regular access to spare parts and maintenance supplies helps extend the life of machinery, reducing costs associated with unexpected repairs and emergency shutdowns.

6. Sustainability

Promoting Responsible Practices: Supplies that meet ecological and sustainable standards help companies reduce their environmental footprint and comply with environmental regulations.

Energy Efficiency: Equipment and materials that promote energy efficiency not only reduce the environmental impact, but also contribute to lower long-term operating costs.

7. Adaptability and Demand Response

Flexibility in production: Adequate supply allows companies to adapt quickly to changing demand or market conditions, ensuring that they can meet orders and maintain customer satisfaction.

Scalability: Availability of supplies facilitates the scalability of operations, allowing companies to increase or reduce production as needed without compromising quality or efficiency.

Strategic Alliances: Maintaining a good relationship with industrial supply suppliers can ensure better prices, more favourable delivery conditions and access to innovative products.

Customer satisfaction: The ability to meet delivery times and offer quality products is directly related to efficient supply management, which positively affects customer satisfaction.

In summary, industrial supplies are essential to maintain efficiency, safety, quality and competitiveness in the industrial sector. Their effective management is key to the long-term success of industrial operations, enabling companies to meet their operational and strategic objectives.