PIMSACORP

LASER SOLDER

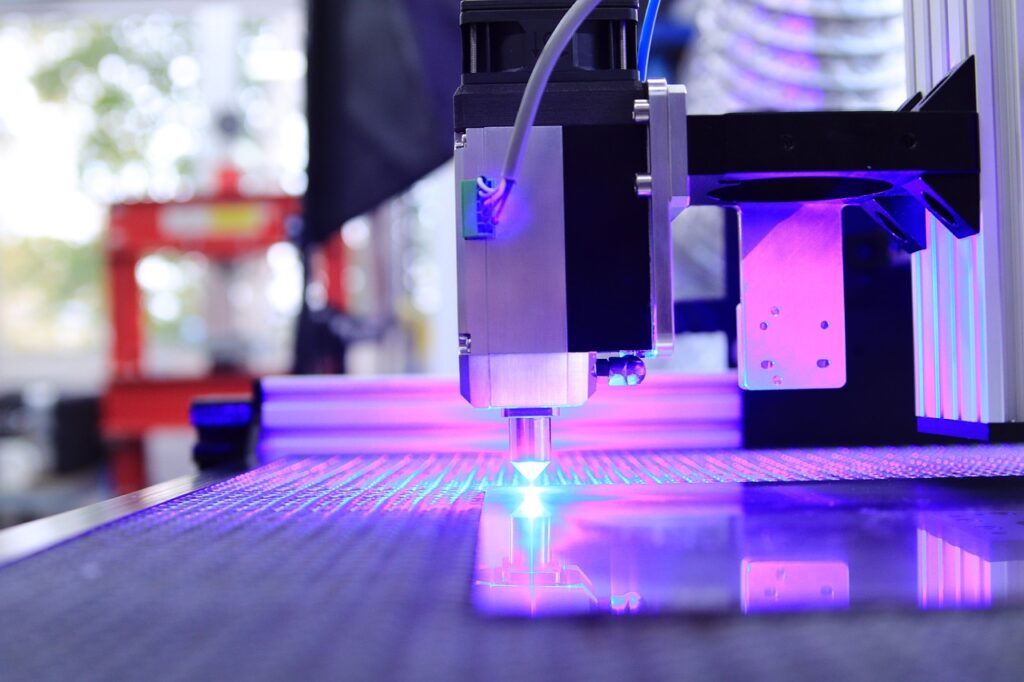

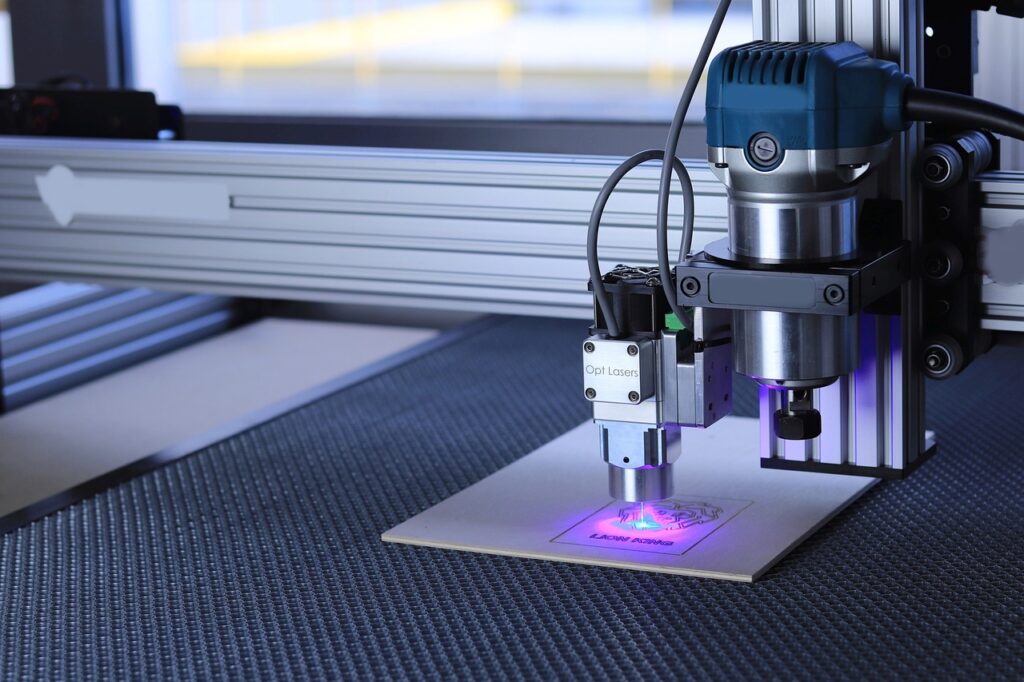

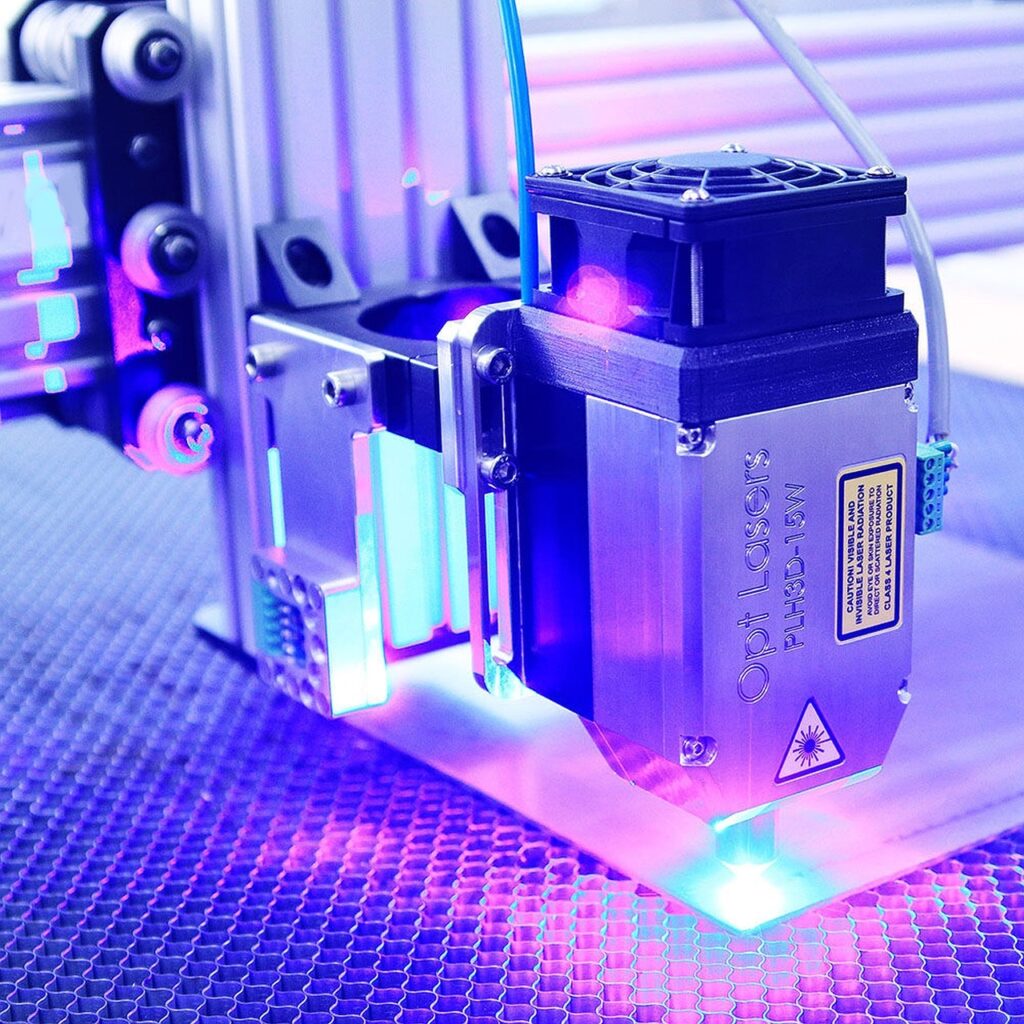

Laser welding is a technology of great importance in industrial enterprises because of its precision, efficiency and ability to work with various materials. Unlike other welding methods, the laser provides extremely precise control over the weld area, resulting in stronger and higher quality joints with less thermal distortion in the parts.

This technology is especially valuable in industries requiring high precision, such as automotive, aerospace, and electronic component manufacturing. Laser welding also allows difficult or dissimilar materials, such as high thermal conductivity metals or exotic alloys, to be welded, thus expanding the design and manufacturing possibilities.

Another key advantage is its ability to easily automate on production lines, increasing productivity and reducing operating costs by minimizing the need for reprocesses and improving consistency of the final product. Also, being a non-contact process, it reduces tool wear, which extends the life of the equipment and decreases maintenance times.

In short, laser welding is crucial in the modern industrial environment for its ability to improve product quality, increase production efficiency, and reduce operating costs.