PIMSACORP

Electrical Control

Electrical controls are systems and devices that manage and regulate the operation of electrical equipment and machines. These controls are essential in industry and many everyday applications for several reasons:

Function of the Electrical Controls:

On and Off Management: Electrical controls enable safe and efficient switching of electrical equipment on and off. This ranges from simple switches to complex automated systems that regulate the operation of industrial machines.

Operating Parameters Regulation: The electrical controls adjust and regulate variables such as speed, voltage, current, temperature and pressure. This is essential to ensure that equipment operates within safe and efficient parameters.

Process Automation: Electrical controls are essential for industrial automation. They allow to program and coordinate the operation of multiple machines, reducing the need for manual intervention and increasing operational efficiency.

Safety and Security: Electrical controls include protective mechanisms that prevent equipment damage or accidents. This may include automatic switches, overload relays and emergency systems that disconnect equipment in the event of failure or hazard.

Monitoring and Diagnosis: Electrical controls allow the status and performance of equipment to be monitored in real time. This facilitates early fault detection, allowing more effective preventive and corrective maintenance.

Remote Control and Monitoring: With the advancement of technology, many electrical controls now allow for remote operation and monitoring via distributed control systems (DCS) or programmable logic controllers (PLC), which facilitates the management of complex facilities from a central location.

Importance of Electrical Controls:

Operational Efficiency: Electrical controls optimize energy and resource use, improving process efficiency and reducing operating costs. Well-controlled machinery works more effectively, using less energy and producing less waste.

Safety: In industrial environments, safety is paramount. Electrical controls ensure that equipment operates within safe limits, protecting both workers and equipment.

Consistency and Accuracy: Electrical controls allow you to maintain consistent and accurate processes, which is crucial for product quality and process reliability. This is particularly important in manufacturing, where even small variations can affect the final product.

Reduced Downtime: By enabling continuous monitoring and automation, electrical controls help reduce downtime due to failure or maintenance, increasing productivity.

Flexibility and Adaptability: Electrical control systems can be programmed and adjusted to suit different production needs or process changes, offering great flexibility.

Regulatory Compliance: In many industries, complying with standards and regulations is crucial. Electrical controls help ensure that equipment operates within parameters required by law or industry standards.

In short, electrical controls are critical to the safe, efficient and automated operation of equipment and processes in a wide variety of applications, from industrial manufacturing to everyday appliances.

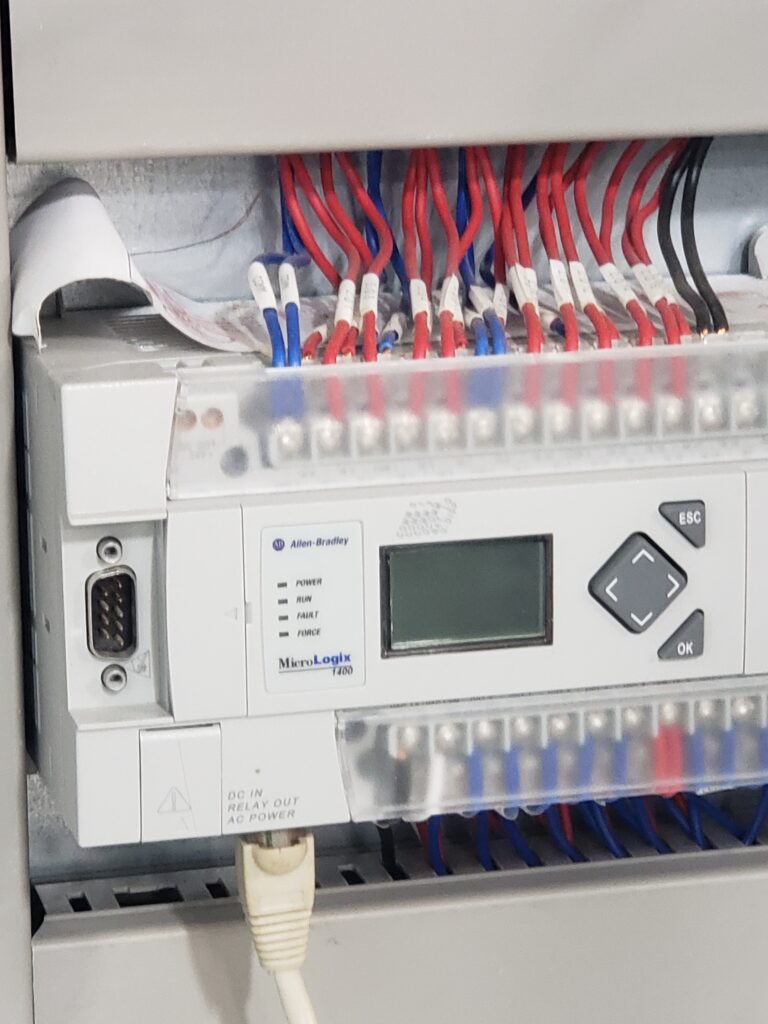

Improperly designed electrical control

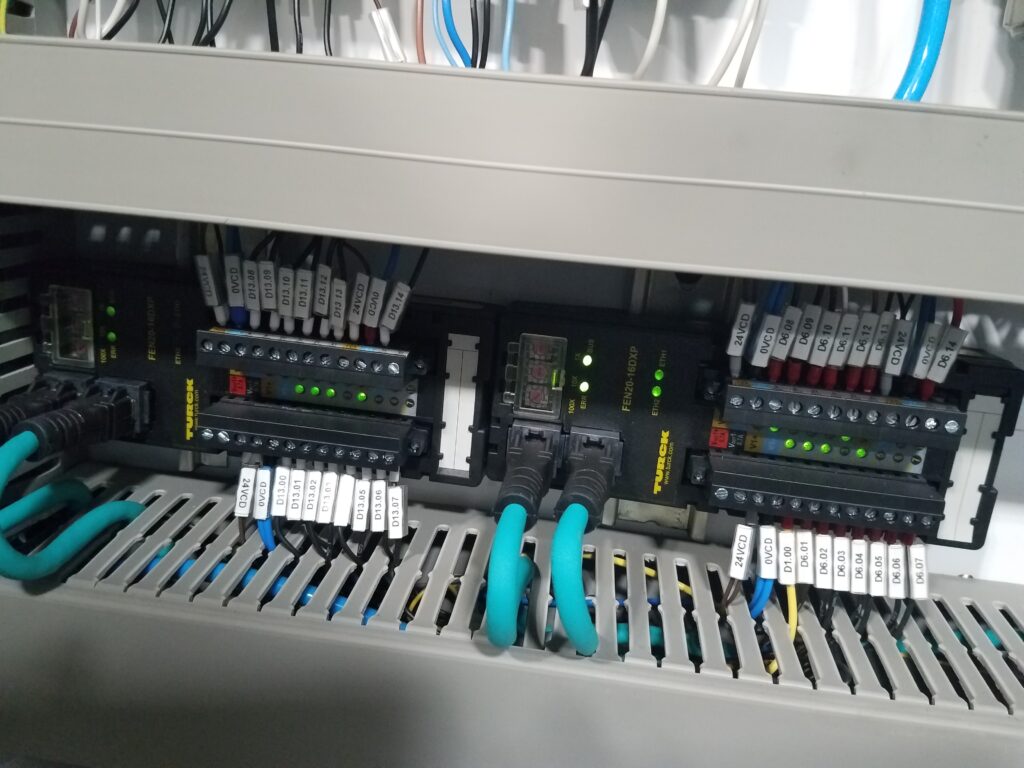

Electric control redesigned by pimsacorp